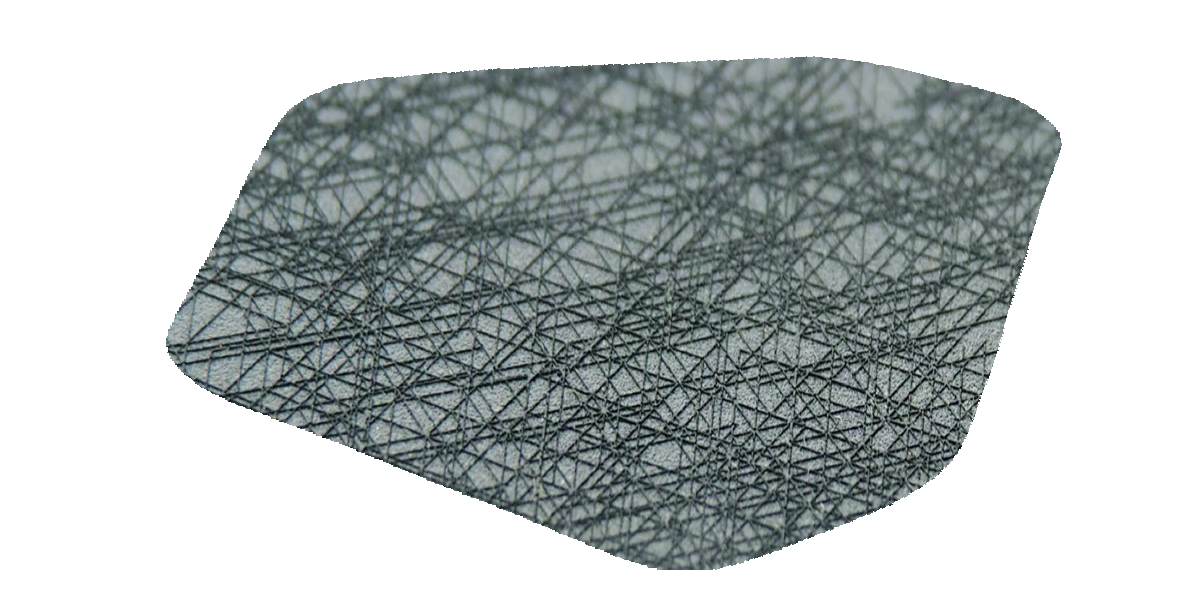

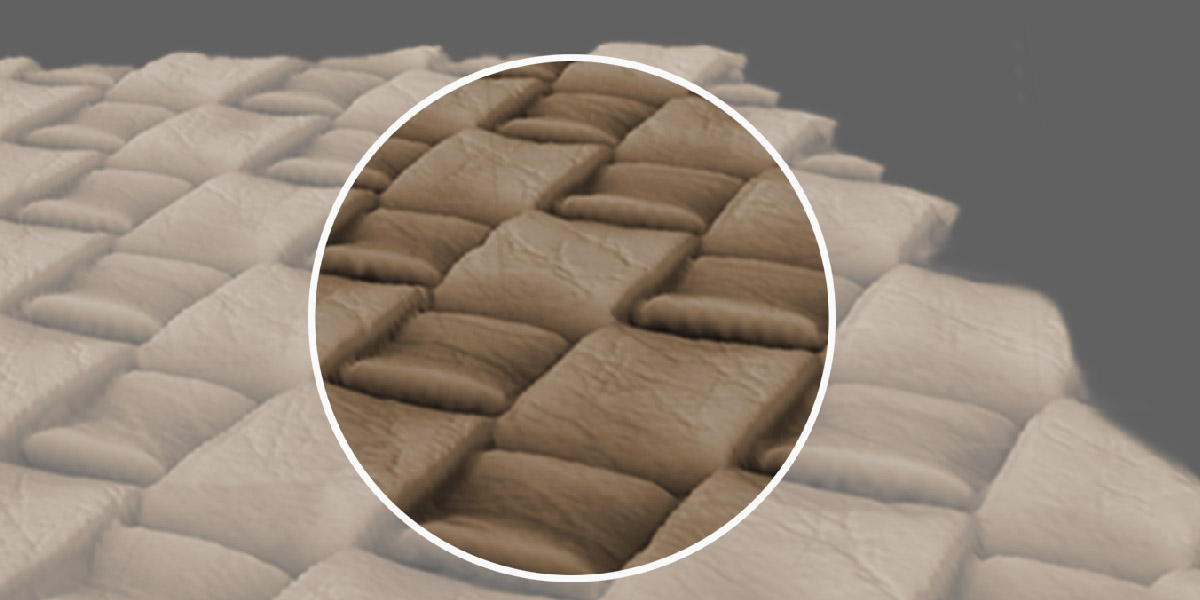

Creating textures for laser engraving or 3D printing requires very specific expertise. With our experience in surface evaluation and a well-established data workflow, we are able to provide a service that users often have little or no staff for.

INQUIRY PHASE

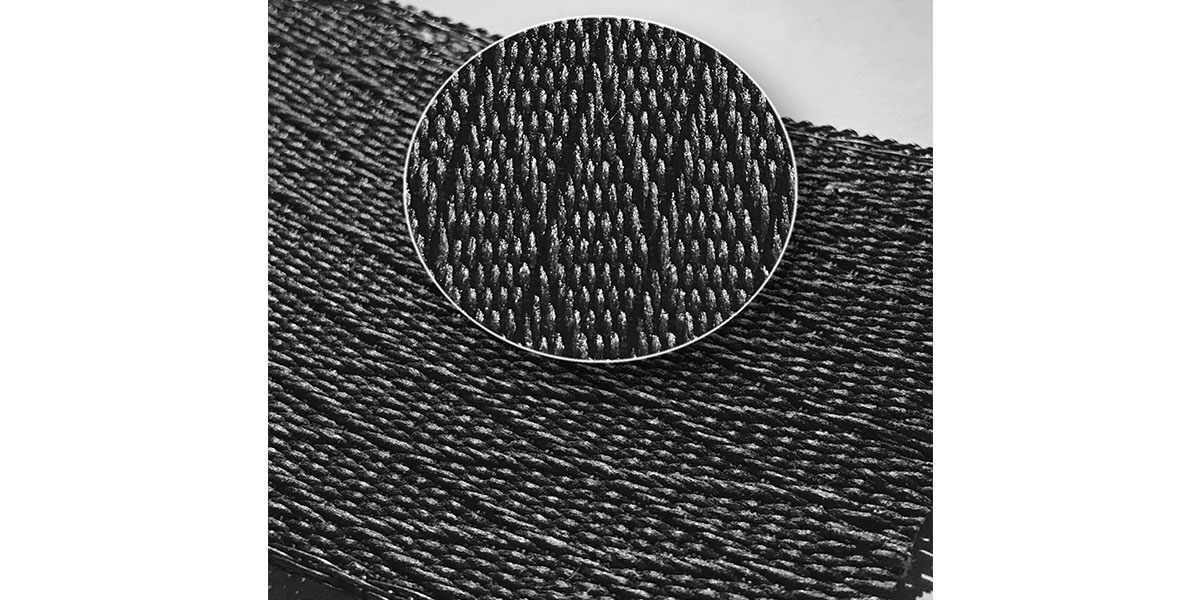

We clarify the feasibility taking into account the material and process parameters.

The basis is customer samples or CAD data as a step format or existing results.

We analyze data and roughness with imaging depth measurements.